- Cable Management Systems

- Control & Auxiliary Cables

- Fire Resistant Cables

- H07RN-F Rubber Cables

- Instrumentation Cables

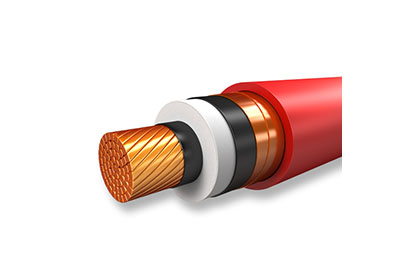

- LV XLPE PVC Insulated Power

- LV PVC Insulated Building

- LV XLPE Insulated LSZH Cables

- LV LSZH Insulated Wires

- LV Panel Wires

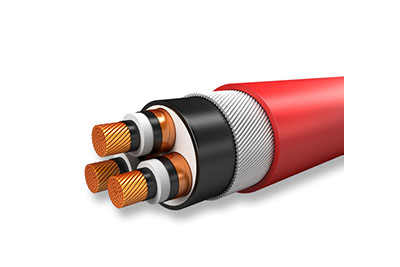

- Medium & High Voltage Cables

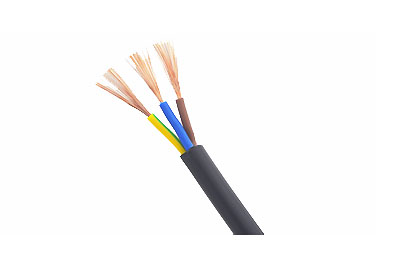

- PVC Flexible Cables

- Submersible Cables

Cable Management Systems

A cable management system, also known as a cable management solution or cable management infrastructure, is a set of components, techniques, and practices designed to organize, protect, and optimize the routing of electrical and data cables within a workspace or infrastructure. It is an essential aspect of modern infrastructure design, whether in offices, data centers, industrial settings, or even at home. Here is a detailed description of cable management systems.

This system is an integral part of any infrastructure where electrical and data cables are used. It contributes to organization, protection, safety, and efficiency while maintaining a neat and tidy appearance. Cable management solutions can range from simple cable ties to complex systems in large data centers, all aimed at ensuring that cables are well-maintained and do not become a hindrance or safety risk.

We Represent

Control & Auxiliary Cables

Control cables are an essential component in various industries and applications, primarily serving the purpose of transmitting electrical signals for the operation and control of machinery, equipment, or systems. These cables are a vital link between control devices, such as switches, sensors, and controllers, and the devices they control, including motors, valves, and actuators.

Auxiliary cables, also known as aux cables or auxiliary audio cables, have a distinctly different purpose. They are primarily intended for transmitting audio signals between electronic devices, enabling the connection of audio sources, like smartphones, MP3 players, laptops, or audio output jacks, to audio playback devices such as headphones, speakers, home stereo systems, or car stereos.

The applications of control cables are diverse and widespread. They are a fundamental component in industrial automation, manufacturing processes, robotics, and HVAC (heating, ventilation, and air conditioning) systems. In these contexts, control cables facilitate precise and reliable communication between control systems and the machinery they oversee. This allows for the execution of commands, regulation of processes, and monitoring of parameters critical to safe and efficient operation.

The applications of auxiliary cables are primarily related to audio transmission and playback. They are commonly used to connect portable audio devices, such as smartphones, tablets, laptops, and music players, to audio output devices like headphones, external speakers, home theater systems, and car audio systems. This enables users to enjoy music, podcasts, and other audio content through a variety of playback devices.

We Represent

Fire Resistant Cables

Fire-Resistant Cable: Enhancing Safety in Critical Environments

Fire-resistant cables, also known as fire-rated cables or simply fire cables, are a specialized category of electrical cables designed to maintain their functionality during a fire emergency. These cables are engineered to withstand high temperatures and maintain electrical integrity, making them crucial in critical applications where the risk of fire is a concern. Below, we delve into the intricacies of fire-resistant cables, discussing their construction, applications, and importance in enhancing safe.

Applications of Fire-Resistant Cables:

Fire-resistant cables find applications in various industries and critical environments where maintaining electrical continuity during a fire is essential. Key applications include:

- Fire Alarm Systems: Fire-resistant cables are used to connect fire detectors, alarms, and control panels. Ensuring the reliability of these connections is vital for early fire detection and response.

- Emergency Lighting Systems: Cables in emergency lighting systems need to remain operational during a fire to guide occupants to safety. Fire-resistant cables play a pivotal role in these systems.

- Voice Evacuation Systems: In large buildings, voice evacuation systems use fire-resistant cables to broadcast evacuation instructions and emergency information during a fire.

- Data Centers: Data centers house critical computing infrastructure. Fire-resistant cables help protect servers, network equipment, and data transmission lines, ensuring minimal downtime during a fire.

- Hospitals: In healthcare facilities, fire-resistant cables are used for critical medical equipment, communication systems, and life-support systems, ensuring uninterrupted patient care.

We Represent

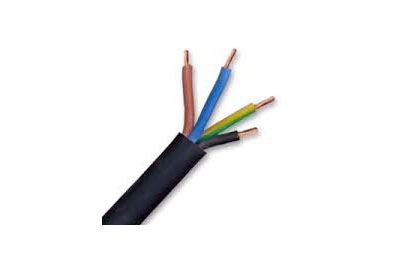

H07RN-F Rubber Cables

H07RN-F rubber cables represent a pinnacle in electrical wiring technology, offering exceptional durability, flexibility, and resistance to a wide range of environmental factors. Whether you’re in the construction industry, manufacturing, or any other sector that requires robust electrical cabling, these cables are a reliable choice. In this comprehensive guide, we will delve into the features, applications, advantages, and standards associated with H07RN-F rubber cables.

H07RN-F rubber cables are designed with a specific focus on robustness and longevity.

To ensure the quality and safety of H07RN-F rubber cables, they adhere to various international standards and certifications. One of the most widely recognized standards is EN 50525-2-21, which governs these cables’ construction, performance, and safety parameters. Compliance with such standards is a testament to the cables’ quality and reliability.

H07RN-F rubber cables are versatile and resilient electrical wiring solutions designed to excel in challenging environments. Their construction, applications, advantages, and adherence to international standards make them a sound choice for various industries and sectors. Their flexibility, resistance to environmental factors, and compliance with stringent standards make them an indispensable component in modern electrical installations.

We Represent

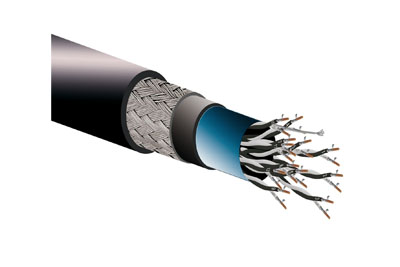

Instrumentation Cables

Instrumentation cables are a vital component of modern industrial and commercial applications, facilitating the reliable transmission of electrical signals in various measurement and control systems. Their role in ensuring precision and accuracy cannot be overstated. In this comprehensive guide, we will delve into the world of instrumentation cables, exploring their construction, applications, advantages, and importance in various industries.

Instrumentation cables are intricately designed to meet the exacting demands of signal transmission.

Instrumentation cables play a pivotal role in ensuring the smooth operation of various industries by enabling precise measurement and control. They provide real-time data to operators, engineers, and control systems, allowing for informed decision-making and process optimization. In sectors like manufacturing, energy, and healthcare, the use of instrumentation cables enhances safety, efficiency, and product quality.

Instrumentation cables must adhere to specific industry standards and certifications to ensure their quality, reliability, and compliance with safety regulations. Depending on the application and region, these cables may conform to standards such as IEC 60079 (for hazardous areas), ANSI/ISA-50.12.01 (for process instrumentation), or UL (Underwriters Laboratories) standards.

We Represent

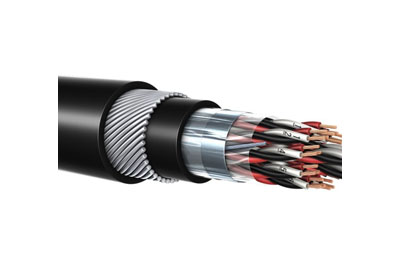

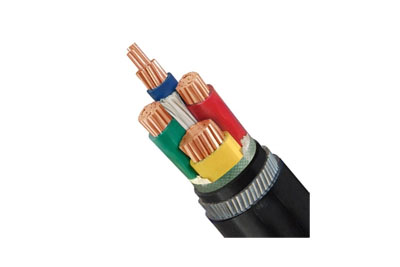

LV XLPE PVC Insulated Power

Low Voltage (LV) XLPE/PVC insulated power cables are an integral part of modern electrical distribution systems, known for their reliability, efficiency, and versatility. These cables play a vital role in transmitting electrical energy from power sources to various destinations, serving a wide range of applications across industries, infrastructure, and residential settings. In this comprehensive guide, we will explore the construction, applications, advantages, and standards associated with LV XLPE/PVC insulated power cable.

LV XLPE/PVC insulated power cables are meticulously engineered to meet the demanding requirements of electrical transmission.

To ensure the quality, safety, and reliability of LV XLPE/PVC insulated power cables, they adhere to international and regional standards and certifications. Common standards include IEC (International Electrotechnical Commission) standards, UL (Underwriters Laboratories) standards, and regional electrical codes.

We Represent

LV PVC Insulated Wires

Low Voltage (LV) PVC insulated building wiring cables are the lifelines of modern buildings, delivering electrical power to every corner of our homes, offices, and infrastructure. These cables are designed to provide a safe and efficient means of electricity distribution within buildings, ensuring that electrical systems function reliably while prioritizing safety. In this comprehensive guide, we will explore the construction, applications, benefits, and standards associated with LV PVC insulated building wiring cables.

LV PVC insulated building wiring cables feature a robust and carefully designed construction to meet the unique demands of electrical distribution within structures.

To ensure the quality, safety, and reliability of LV PVC insulated building wiring cables, they adhere to international and regional standards and certifications. Common standards include IEC (International Electrotechnical Commission) standards, UL (Underwriters Laboratories) standards, and local electrical codes and regulations.

Low Voltage PVC insulated building wiring cables are the backbone of electrical distribution within modern structures. Their construction, applications, advantages, and adherence to standards underscore their importance in powering homes, offices, industries, and infrastructure. These cables not only ensure efficient power distribution but also prioritize safety, making them a crucial component of our built environment.

We Represent

LV XLPE Insulated LSZH Cables

Low Voltage (LV) XLPE Insulated LSZH (Low Smoke Zero Halogen) cables represent a significant leap forward in the realm of electrical cables, offering a combination of safety, sustainability, and reliability. These cables are designed to provide a safe and efficient means of electrical distribution while minimizing the release of toxic smoke and gases in the event of a fire. In this comprehensive guide, we will explore the construction, applications, benefits, and standards associated with LV XLPE Insulated LSZH cables.

LV XLPE Insulated LSZH cables are engineered with a focus on safety and sustainability, with key components designed to minimize environmental and health risks.

To ensure the quality, safety, and reliability of LV XLPE Insulated LSZH cables, they adhere to international and regional standards and certifications. Common standards include IEC (International Electrotechnical Commission) standards, UL (Underwriters Laboratories) standards, and local electrical codes and regulations. Compliance with these standards is essential to guarantee the cables’ performance and safety characteristics.

Low Voltage XLPE Insulated LSZH cables represent a significant advancement in electrical cable technology, offering a unique combination of safety, sustainability, and reliability. Their construction, applications, benefits, and adherence to standards underscore their importance in powering structures while prioritizing safety and minimizing environmental impact. These cables provide a forward-thinking solution for various applications, contributing to the safety, efficiency, and sustainability of electrical distribution systems in residential, commercial, industrial, and public infrastructure settings.

We Represent

LV LSZH Insulated Wires

Low Voltage (LV) LSZH (Low Smoke Zero Halogen) insulated wires represent a significant advancement in electrical wiring technology, offering a combination of safety, sustainability, and reliability. These wires are designed to provide a safe and efficient means of transmitting electricity while minimizing the release of toxic smoke and gases in the event of a fire. In this comprehensive guide, we will explore the construction, applications, benefits, and standards associated with LV LSZH insulated wires.

To ensure the quality, safety, and reliability of LV LSZH insulated wires, they adhere to international and regional standards and certifications. Common standards include IEC (International Electrotechnical Commission) standards, UL (Underwriters Laboratories) standards, and local electrical codes and regulations. Compliance with these standards is essential to guarantee the wires’ performance and safety characteristics.

Low Voltage LSZH insulated wires represent a significant leap forward in electrical wiring technology, offering a unique combination of safety, sustainability, and reliability. Their construction, applications, advantages, and adherence to standards underscore their importance in powering structures while prioritizing safety and minimizing environmental impact. These wires provide a forward-thinking solution for various applications, contributing to the safety, efficiency, and sustainability of electrical distribution systems in residential, commercial, industrial, healthcare, and public infrastructure settings.

We Represent

LV Panel Wires

Low Voltage (LV) panel wires are the unassuming heroes of electrical distribution systems, providing the vital connections between electrical panels, distribution boards, circuit breakers, and the various components of an electrical system. These wires are the nervous system of buildings and industrial facilities, facilitating the efficient flow of electricity to power lights, appliances, machinery, and more. In this comprehensive guide, we will delve into the construction, applications, advantages, and standards associated with LV panel wires.

Low Voltage panel wires are the unsung heroes of electrical distribution systems, forming the critical connections that enable electricity to flow safely and efficiently to power our lives. Their construction, applications, advantages, and adherence to standards underscore their importance in residential, commercial, industrial, and infrastructure settings. These wires provide the backbone for our electrical systems, ensuring reliability, safety, and efficiency in the distribution of electricity. In essence, LV panel wires play a vital role in modern society by powering our homes, businesses, industries, and infrastructure, contributing to the functionality, productivity, and comfort of our daily lives.

We Represent

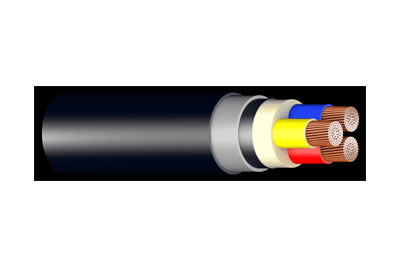

Medium & High Voltage Cables

Medium and High Voltage (MV & HV) cables are the lifelines of electrical grids and power distribution networks, tasked with the efficient and reliable transmission of electrical energy over long distances. These cables are engineered to handle the unique challenges of high voltage electrical systems, ensuring the safe and efficient distribution of power to industries, homes, and infrastructure. In this comprehensive guide, we will explore the construction, applications, advantages, and standards associated with Medium and High Voltage cables.

Medium and High Voltage cables are the arteries of modern electrical grids and power distribution systems, ensuring the efficient and reliable transmission of electrical energy across vast distances. Their construction, applications, advantages, and adherence to standards underscore their pivotal role in powering industries, homes, and infrastructure. These cables are at the core of our electrical infrastructure, providing the essential link between power generation and consumption, supporting the growth of industries, and enabling the integration of renewable energy sources. Medium and High Voltage cables are the backbone of our electrical power systems, contributing to the reliability, efficiency, and safety of our modern society.

We Represent

PVC Flexible Cables

PVC (Polyvinyl Chloride) flexible cables are a cornerstone of electrical wiring systems, known for their versatility, durability, and ability to adapt to a wide range of applications. These cables are engineered to provide reliable electrical connections while accommodating the bending, twisting, and movement inherent in various settings. In this comprehensive guide, we will explore the construction, applications, advantages, and standards associated with PVC flexible cables.

PVC flexible cables are the workhorses of electrical wiring systems, providing the adaptability and durability required in today’s dynamic electrical environments. Their construction, applications, advantages, and adherence to standards underscore their importance in powering our homes, businesses, industries, and infrastructure. These cables are essential components of our modern electrical systems, supporting the reliable and flexible transmission of electricity while ensuring safety and durability. PVC flexible cables contribute to the efficiency, versatility, and cost-effectiveness of electrical installations across a wide range of settings.

We Represent

Submersible Cables

PVC (Polyvinyl Chloride) submersible cables are specialized electrical cables designed to function efficiently and reliably underwater or in other submerged applications. They are an integral part of various industries, ensuring power supply in challenging environments such as boreholes, underwater pumps, and submersible equipment. In this comprehensive guide, we will delve into the construction, applications, advantages, and standards associated with PVC submersible cables.

PVC submersible cables are the lifeline of submerged electrical systems, providing reliable and efficient power transmission in challenging environments. Their construction, applications, advantages, and adherence to standards underscore their importance in powering agriculture, mining, oil and gas, water treatment, and renewable energy industries. These cables play a crucial role in ensuring the availability of electrical power where it’s needed most, even in the depths of water-filled boreholes, mines, and offshore installations. PVC submersible cables are a testament to engineering innovation, enabling industries to harness the power of electricity in environments where traditional cables would falter.

We Represent